In today’s dental labs, zirconia furnaces play a pivotal role in the production of high-quality dental restorations. These furnaces rely on heaters to achieve the high temperatures necessary for sintering zirconia, making heaters a regular consumable that requires periodic replacement. Finding the right heater supplier is crucial for ensuring optimal furnace performance and minimizing downtime. This blog post guides you through the process of selecting the perfect heater for your dental lab’s zirconia furnace.

Understanding Zirconia Furnaces and Their Heaters

Zirconia furnaces are essential for creating strong, durable, and aesthetically pleasing dental restorations. The heater, a critical component of the furnace, generates the extreme heat required for sintering. Over time, heaters degrade due to the high temperatures and prolonged usage, making them regular consumables that need to be replaced to maintain furnace efficiency.

The Importance of Custom-Fit Heaters for Your Existing Furnace

Custom-fit heaters are designed to match the specific dimensions and requirements of your zirconia furnace, ensuring optimal performance and longevity. A poorly fitted heater can lead to uneven heat distribution, reduced efficiency, and even furnace damage. To avoid these issues, it’s crucial to find a supplier that offers custom-fit heaters tailored to your specific furnace model.

Key Factors to Consider When Looking for a Heater Supplier

- Expertise and Experience: Choose a supplier with a deep understanding of dental lab tools to ensure they provide high-quality products that meet your needs.

- Customization Options: The supplier should offer custom-fit heaters designed to match your furnace’s specifications perfectly.

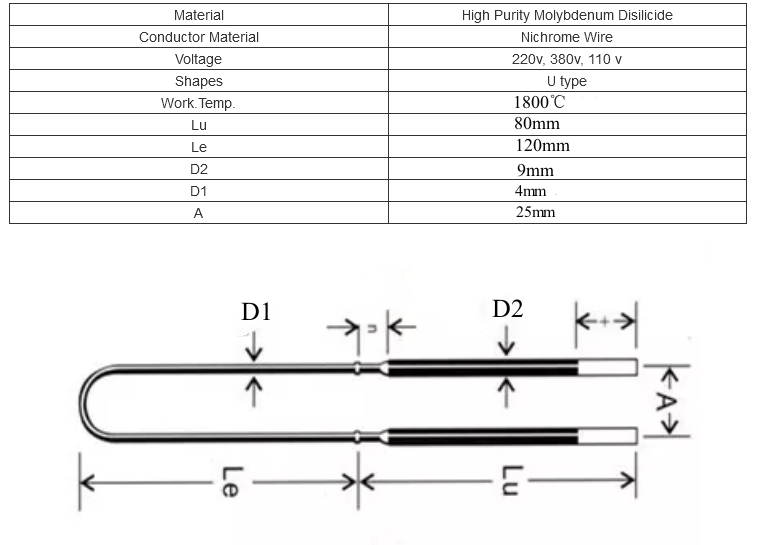

- Quality and Compatibility: Ensure the heater material and design are compatible with your furnace. High-purity molybdenum disilicide is an excellent material choice due to its high-temperature resistance and durability.

- Customer Support and Service: A reliable supplier should provide technical support and responsive customer service to address any issues promptly.

Top Dental Lab Suppliers for Custom-Fit Zirconia Furnace Heaters

One standout supplier in the dental lab industry is Dental Lab Shop. They offer high-quality sintering furnace heating elements made of high-purity molybdenum disilicide, with a maximum working temperature of 1600°C. Their in-stock products are compatible with popular furnace models like the Zirkonzahn 600.

What sets Dental Lab Shop apart is their custom-making service. By providing specific chart data (L, U, A, D1, D2), overall length, heat and cool part length, diameter, and distance information, they can create a custom-fit heater tailored to your furnace within just five days. This level of customization ensures optimal performance and extends the lifespan of your zirconia furnace.

Tips for Maintaining and Extending the Lifespan of Your Zirconia Furnace Heater

- Regular Cleaning and Maintenance: Keep your furnace and heater clean to prevent the buildup of residue that can affect performance.

- Proper Usage and Handling: Follow the manufacturer’s guidelines for operating your furnace to avoid unnecessary wear and tear on the heater.

Signs of Replacement: Watch for the following signs that indicate it’s time to replace your heater:

- Reduced Efficiency: If your furnace is taking longer than usual to reach the desired temperature or is struggling to maintain it, the heater may be losing its effectiveness.

- Uneven Heating: Inconsistent heating patterns can indicate that the heater is not functioning properly. This can lead to poor-quality sintering and compromised dental restorations.

- Visible Damage: Inspect the heater for any physical signs of damage, such as cracks, warping, or discoloration. These issues can significantly impact the heater’s performance.

- Severe Oxidation: Check the conductive end of the heater for signs of severe oxidation. If you notice a powdery substance or significant corrosion, it’s a clear indication that the heater needs to be replaced. Oxidation can reduce the heater’s conductivity and overall efficiency.

Conclusion

Finding the right heater supplier is essential for maintaining the efficiency and longevity of your dental lab’s zirconia furnace. Suppliers like Dental Lab Shop offer high-quality, custom-fit heaters that ensure optimal performance. By prioritizing quality and customization, you can keep your dental lab running smoothly and produce top-notch dental restorations.