Blog

Light-Cured Custom Trays: Revolutionizing Removable Full Denture Impressions for Superior Patient Outcomes

Streamlined Denture Fabrication: Light-Cured Resin Custom Tray Sheets

In the field of prosthodontics, creating precise, comfortable removable full dentures remains a critical service that millions of patients depend on. Despite technological advances in digital dentistry, the fabrication of complete dentures continues to rely on exceptional impression techniques that capture both static anatomy and functional movements. Light-cured resin custom tray sheets represent a significant advancement in this specialized area of dentist supplies, offering remarkable benefits over traditional methods.

-

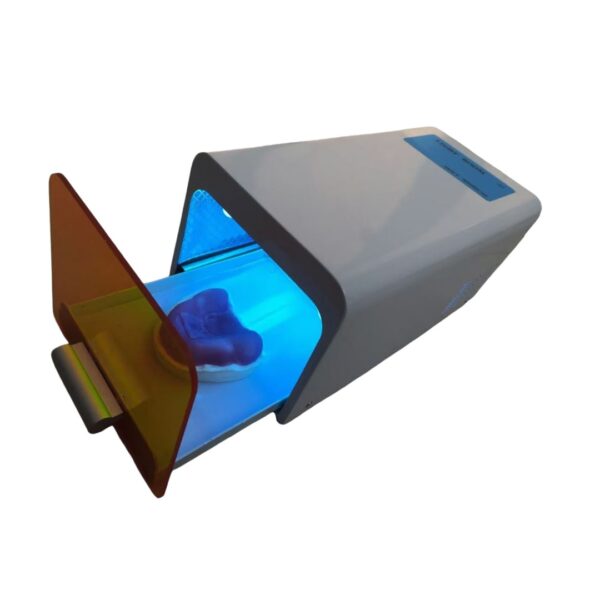

Light Curing Unit for Dental Laboratories Polymerization

Original price was: $419.00.$308.00Current price is: $308.00. -

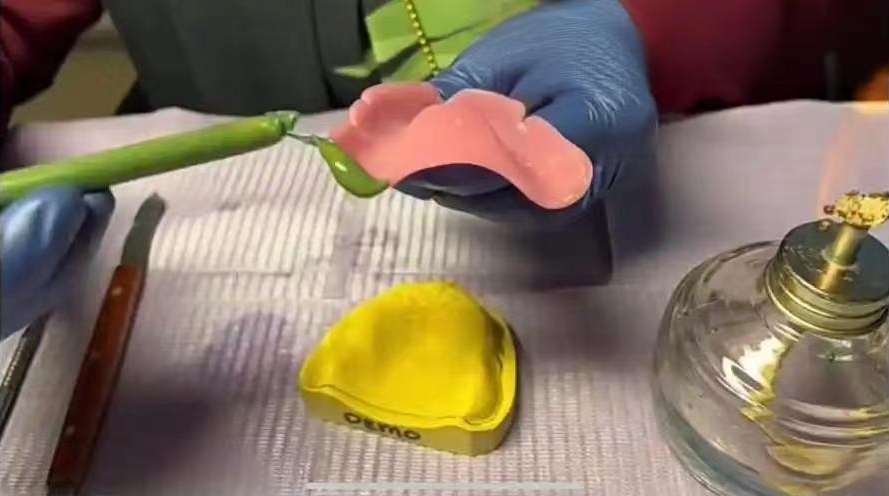

GC Pink Dental Finishing Wax Strips – Achieve Perfect Denture Margins

Original price was: $75.00.$54.00Current price is: $54.00. -

Pneumatic Dental Lab Denture Injection System

Original price was: $1,100.00.$809.00Current price is: $809.00. -

Dental Lab Resin Sheet: Create Complete Removable Denture

$116.00

The Challenge of Complete Denture Impressions

Creating successful removable complete dentures begins with accurate impressions that capture not just the static anatomy, but also the dynamic functional movements of oral tissues. While digital intraoral scanners excel at capturing fixed oral structures, they cannot adequately record the crucial border movements and tissue displacement necessary for optimal denture retention and stability.

This limitation highlights why custom impression trays remain essential in full denture fabrication. A precisely fitted custom tray allows dentists to capture the functional movements that determine a denture’s success—the way tissues move during speaking, swallowing, and facial expressions.

Limitations of Traditional Custom Tray Fabrication

Conventional methods for creating custom impression trays for complete dentures typically involve labor-intensive processes using wax patterns or self-curing acrylic resins. These approaches present several challenges:

Self-curing acrylic resins release potentially harmful monomers, requiring careful handling and adequate ventilation. The exothermic reaction during polymerization can cause material warping, compromising accuracy. Additionally, the time-consuming mixing, molding, and setting process extends chair time and reduces practice efficiency.

Wax-based methods, while less hazardous, lack the rigidity and dimensional stability needed for precise impression-taking, especially during functional movements when creating removable dentures.

Light-Cured Resin Custom Tray Sheets: A Superior Alternative

The introduction of light-cured resin custom tray sheets represents a significant advancement for dental professionals specializing in removable prosthodontics. These innovative materials offer several advantages that transform the full denture fabrication workflow:

- Precise Adaptation: The malleable pre-polymerized sheets adapt perfectly to master casts, ensuring exceptional fit against the patient’s tissues. This precision is crucial for complete denture success.

- Dimensional Stability: Unlike traditional materials, light-cured resins maintain their shape without warping or distortion, providing reliable impression platforms for removable denture fabrication.

- Enhanced Workflow Efficiency: The rapid curing process—typically 3-5 minutes under appropriate light—dramatically reduces fabrication time compared to conventional methods, allowing dental practices to optimize their complete denture workflow.

- Minimal Shrinkage: The controlled polymerization process results in minimal dimensional changes, ensuring the custom tray accurately represents the patient’s anatomy.

- Improved Patient Experience: The absence of strong odors and reduced chair time enhances patient comfort during the complete denture fabrication process.

- Superior Handling Properties: The material remains stable yet adaptable during fabrication, allowing for precise modifications for special anatomical considerations in full denture cases.

Integration with Modern Curing Light Units

The effectiveness of light-cured resin custom tray sheets depends on proper polymerization using appropriate curing light units. Modern LED curing lights deliver specific wavelengths (typically 460-480nm) that efficiently activate the photoinitiators in the resin material. This technology ensures complete polymerization throughout the tray thickness, creating a rigid, stable impression platform essential for capturing the precise details needed for successful removable dentures.

For dental practices specializing in removable prosthodontics, investing in quality curing units optimizes the workflow and ensures consistent results in complete denture fabrication.

Conclusion

For dental professionals committed to delivering exceptional removable denture solutions, light-cured resin custom tray sheets represent an essential advancement in dentist supplies. By combining precision, efficiency, and patient comfort, these materials help overcome the limitations of both digital scanning and traditional tray fabrication methods, ultimately supporting the creation of comfortable, functional complete dentures that enhance patients’ quality of life.