Blog

GET TO KNOW ABOUT THE FAME OF VACUUM FORMING MATERIALS DENTAL

Dentistry vacuum former

The vacuum formers in the dental industry are getting more popular and using this technology many dental appliances have been manufactured. The dental appliances manufactured using vacuum formers are sports mouth guards, bleach trays, and other orthodontic appliances.

Depending on the thickness and uses, this technology will use a variety of thermoplastics. The vacuum forming materials will vary depending on the needs. If you are planning for the vacuum former in your dental lab, then you have reached the place.

What is the role of vacuum former?

Vacuum former is one of the manufacturing methods which are used to shape plastic materials. During the vacuum forming process, a sheet of plastic is heated and it is pulled around a single mold using the suction process.

The vacuum process is used in various fields and now, the dental industry started using the process. It is used to manufacture various kinds of mouthguard material sheets, bleaching trays, indirect bonding trays, and other dental appliances. This is a streamlined manufacturing method, so it is getting more popular in the dentistry field.

The vacuum former comes with a vacuum pump and heating element, and once the heating element is ready the plastic sheet and the dental appliances can be placed and the vacuum will start to generate, resulting in the dental vacuum forming sheets. Both vacuum former and the dental thermoformed follow the same process but the vacuum former requires the compressed air connection and also it is louder than the counterpart dental thermoforming. If you are looking for an economical option then vacuum former will be the right choice.

Vacuum forming materials used in dentistry:

The dental vacuum forming materials come in different varieties but they all differ in atomic makeup, properties, and a range of additives. But there are some common characteristics that every vacuum-forming material dental should share. Those characteristics include thermal strength, good flow, low forming temperature, high impact strength, and doesn’t get shrink when it is cooled.

Even though there are lots of vacuum forming materials but only certain materials can be used in the dentistry application. The most common material used in dental applications is Acrylonitrile Butadiene Styrene (ABS).

ABS is an amorphous thermoplastic material that is hard and rigid, and it contains rubber so it will have great impact strength. This is the most popular material in the dental field, as it comes with a different range of thicknesses and they can produce dental appliances in different textures and finishing. This is considered the safest material and using this we can make rigid and molded products.

Best vacuum forming products recommended:

The dental industry is introducing a lot of computer-based technology and there is much equipment that is dependent on CAD-CAM technology. Dental Lab Shop, is an online dental place to buy all kinds of dental materials, supplies, and products. This will be the best place to buy high-quality prices at the lowest rate.

We have recommended some of the best vacuum forming products from the Dental Lab Shop;

This dental vacuum forming sheet is rigid and transparent, and it is used in the dentistry lab to manufacture different kinds of appliances. It comes with excellent weather ability and chemical-resistant properties from fading.

This orthodontic dental vacuum forming sheet is to make retainers, splints, provisional, temporary acrylic bridges, and other vertical dimension applications. There will be no bubbles and also the thermal effect of this product will be excellent.

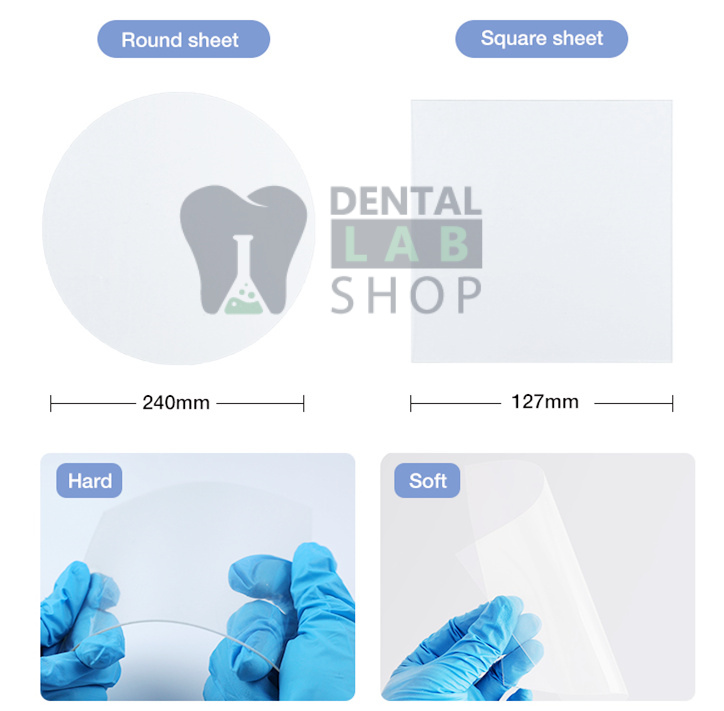

The vacuum forming retainer machine is an excellent option for fabricating thermoplastic appliances. This is entirely made of aluminum and this can be used mostly for square and round-shaped thermoplastic vacuum former sheet materials. This orthodontic retainer machine has a unique rotating frame that will allow heating on both sides of the sheets.

Some of the characteristics of this retainer machine include;

- The machine has a special ceramic heating element that will ensure to provides uniform heating

- Also, there is a cast rack with beads and it is one of the benefits while making splints

- The heater is made of carbon fiber so it will come for a long time

- Offers retention removal of the model

Dental thermoforming machines or thermoplastic machines are considered the molding machines for the thermoplastic plates. They are used in the dental industry to manufacture baseplates, individual trays, crowns and bridges, orthodontic appliances, and splints.

The dental thermoforming machine can adapt a plastic sheet to the shape you want under heat and pressure. This is a self-contained unit and here you don’t have to apply extra vacuum using a separate airline as it will produce a strong vacuum.

This vacuum forming machine comes in a robust and ideal design so it will form all kinds of dental appliances in just 5 minutes. Every dental industry should need this kind of equipment as it is cost-saving and also quickly manufacture the product as per your wish.

There is a heavy-duty downdraft vacuum motor that features a symmetrical heating system and it helps to achieve even heat distribution and corrosion resistance.

Some of the features of this dental thermoforming machine;

- Precise downward suction

- It delivers the heat evenly

- It is an adjustable and rust-resistant body

- It is specially used for a wide range of clinical applications

- Comes with a non-rotating system so it will make the operation easier

- Compatible with all kinds of dental thermoplastics

Bottom Line:

The vacuum forming materials dental is the most cost effective and versatile product, and the materials that undergo such a process will involve heat, stretching, and vacuuming. The vacuum method is the talk of the town in the dental industry.

If you want to implement this vacuum forming process in your dental lab, then you need the right equipment. Looking for the right place, yes here is one, which is Dental Lab Shop. Here, they supply high-quality materials and equipment at an affordable rate. Click here to learn more about the dental vacuum forming materials: